Soil Stabilization

Soil Stabilization

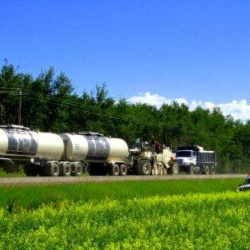

SOIL STABILIZATION is the application of general use Portland cement blended with variety of additives (Type C Fly Ash, Lime/Cement Kiln Dust) has gained rapid acceptance to rework existing roadways to match the needs of resource industries, provincial and municipal roadways, wind farms and large scale farm operations. The chemical alteration of sub grade clay into a granular material that allows water to pass through provides a road base with minimal road user disruption. Completing or covering these composite structures with a graded aggregate seal coat will keep costs down in rural areas. Calcium and Magnesium Chloride are also being reviewed for their application as chemical stabilizers. Due to the amount of clay in Alberta and Saskatchewan, Cement Stabilization has been one of the fastest growing techniques used to stabilize bases in Western Canada.

Prior to construction, the existing roadway is analyzed for current structural capacity and materials assessment, with core samples being extracted for laboratory analysis. These samples aid designers and owners in determining which stabilizing additives and dosages should be used to achieve optimal results.

Using the results of the detailed laboratory analysis, the design engineer may choose one of the following stabilizing agents:

BITUMINOUS STABILIZATION

Contractors can inject either asphalt emulsion or foamed/expanded asphalt directly into the cutter drum while the pulveriser is coupled to a nurse unit. This application is best suited for older oxidized asphalts, soil cement materials, and clean granular/ bituminous structures. Expanded asphalt achieves very good success while utilizing liquid asphalt injection into granular mixes. Previously chip sealed or oiled roads can be reconstructed in situ to meet municipal needs/current loading requirements.

FULL DEPTH RECLAMATION

FULL DEPTH RECLAMATION “FDR” is a rehabilitation technique that allows agencies to pulverize the full thickness of asphalt or other road surfaces while incorporating a pre-determined portion of the underlying materials (base, sub base or sub grade) to uniformly blend and create a homogeneous construction material. Generally speaking, agencies will choose to add an oil based product such as foamed asphalt or cement stabilization at the mixing stage to create a firm base.

MECHANICAL STABILIZATION

Agencies have the ability to alter current roadway gradation matrices at minimal cost by pulverizing local aggregate, reclaimed asphalt pavement (RAP), or concrete rubble into the road for a desired gradation and to help strengthen particle interlock. Full Depth Reclamation “FDR” will often require a combination of stabilizing agents to optimize the quality and physical properties of the reclaimed mix. Regardless of the stabilizing agent chosen, a laboratory mix design must be undertaken prior to construction to determine the best possible project specific outcome.